Proiect Cric Cu Dubla Actiune

-

Upload

mihai-belu -

Category

Documents

-

view

224 -

download

0

Transcript of Proiect Cric Cu Dubla Actiune

-

8/10/2019 Proiect Cric Cu Dubla Actiune

1/16

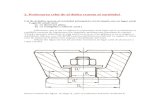

Project Theme

Lifting mechanism tyle : Double action lifting jack.

Maximum load Q = 30500 N

Maximum elevation H = 245 mm

Fig 1.

1.

Calculus of the main screw

1.1

Choosing the material

OL 50

1.2

Predimensioning Calculus

Load Calculus Qc

Qc= Q = 1,3 30500 = 39650 N

= 1,251,3

Interior diameter of thread, d3

c= 60..80 MPa

d3 will be taken as d3 = 25 mm

Choosing of the thread

Nominal

diameter

Pace Medium

Diameter

Exterior

Diameter

Interior Diameter

d1 p1 d2=D2 D4 d3 D1

32 6 29 33 25 26

Table 1

-

8/10/2019 Proiect Cric Cu Dubla Actiune

2/16

1.3. Checking the autobreaking condition

Pitch angle of the screw, 2

Initial friction angle,

Condition 2 < 1.4. Verifying at stresses

Torsion moment which loads Mtscrew, Nmm

Fig 2

Compression tension c , MPa Tension Torsion c , MPa Equivalent tension e , Mpa

79,78

-

8/10/2019 Proiect Cric Cu Dubla Actiune

3/16

1.5 Verifying at buckling

Coefficient

= 23,6

lf=Klbuckling length lf= 0,5 295 = 147,5k=0,5

l=Hl+m=245+50=295

m=50

Fig 3

Buckling domain

-

8/10/2019 Proiect Cric Cu Dubla Actiune

4/16

2.

Calculus of the secondary screw

2.1

Choosing the material

OL50

2.2

Calculus of spire number of principal screw nut

z=9

pa=7..13

Fig 4

Length of the nut

Hph=zP=96=54 mm

2.3

Choosing the exterior thread

d3=D0+(8..10) mm = 37 + 8 = 45 mm

D0=D4+(4..6) mm = 33 + 4 = 37 mm

Choosing the standard thread

Trapezoidal thread standard, with normal pace STAS SR ISO 2904

Nominal diameter Pace Medium diameter Exterior diameter Interior diameter

d1 p1 d2=D2 D4 d3 D1

55 9 50 56 45 46Table 2

-

8/10/2019 Proiect Cric Cu Dubla Actiune

5/16

2.4

Verifying the autobreaking condition

Inclination angle of the threads spira

2.5

Verifying at stresses

Tension Moment, Mt, Nmm Effective compression tension, c, MPa

Torsion Tension Equivalent Tension, e

ac = 60..80ace Condition accomplished

3.

Nut Calculus

3.1

Choosing the material

OL50

3.2

Nr. Of spirals Length of the nut

Hph= zp = 96 =54 mm

-

8/10/2019 Proiect Cric Cu Dubla Actiune

6/16

Fig 5

3.3 Verifying the spiral

Bending moment

Fig 6

-

8/10/2019 Proiect Cric Cu Dubla Actiune

7/16

At Shearing 3.4

Choosing the nut dimensions

Exterior body diameter Exterior neck diameter Height of the neck

Fig 7

3.5

Verifying the nut

Effective traction torsion Effective torsion tension Equivalent tension

-

8/10/2019 Proiect Cric Cu Dubla Actiune

8/16

3.6

Verifying the neck

Verifying at crushing

Mpa

Verifying at shearing 3.7

Choosing and verifying threaded beak which holds the nut in the lifting mechanism body

M5x25 mm

Thread t n c1 d4 c3 d1 mM5 1.6 0.8 1.2 3.5 3 2.5 2

Table 3

Fig 8

Friction moment on the beads surface Mg, Nmm

Moment which loads the bead

-

8/10/2019 Proiect Cric Cu Dubla Actiune

9/16

4.

Body calculation

Fig 9

Choosing dimensions

Dei=De+(2..6) mm = 65+5=70 mm

=5..7 => =6

=10..12=> =11

Dbe= DB i+ (30..50) mm

H1 = HII + (30..50) = 280 mm

HII=H=245

Hc=H1 + Hphhg + (0..10) = 280+48-10+10=328 mm

Dbi = 124 mm

Dbe = 174 mm

Verifying at compression

Verifying at crushing

-

8/10/2019 Proiect Cric Cu Dubla Actiune

10/16

5.

Cup calculus

5.1

Cup of the double action telescopic lifting jack

Choosing the beak which puts in place the principal screw

ds=(0,15..0,25)dc = 7

dc=d+(2..4) mm= 32+3 =35

d=nominal diameter of the principal screw

Verifying the beak

At shearing

At crushing : Beak - cup

: Beak- head of the screw

Fig 10

-

8/10/2019 Proiect Cric Cu Dubla Actiune

11/16

Verifying the shrinked section of the head of the screw at stresses

Condition accomplished6.

The efficiency of the double action lifting jack

d2I = 29

d2II=50

tg2I=0.065tg2II=0.057

The efficiency of the double action lifting jack is 32 % .

-

8/10/2019 Proiect Cric Cu Dubla Actiune

12/16

-

8/10/2019 Proiect Cric Cu Dubla Actiune

13/16

Length of the crank , L

3. Calculus of the attachement

Length of the attachement , Lp

Diameter of the attachement , dpe

Attachement made of pipe

(] I choose Commercial Pipe 32x1/OL 50

4. Calculus of the socketswheel

Choosing the material : OL50

4.2 Choosing dimensions

-

8/10/2019 Proiect Cric Cu Dubla Actiune

14/16

Fig 12

4.2 Verifying the wheel at loads

Verifying the theet at bending

Verifying the theet at shearing

Verifying the contact surface of the theet at crushing

Verifying the assembling on the polygonal boundary at crushing

-

8/10/2019 Proiect Cric Cu Dubla Actiune

15/16

4.3 Calculus of the socket

Choosing the material : OL60 STAS 500/2

Choosing dimensions

The dimensions of the socket , mm :

h=10,16

l2= l1 +

mm

Verifying the socket at crushing

4.4 Th lulu h k blChoosing the material

OL50 STAS 5754/2/OL50

Verifying the bolt at loads

Verifying at shearing

-

8/10/2019 Proiect Cric Cu Dubla Actiune

16/16

Verifying the bolt at crushing

Verifying the bolt at bending