Tehnica de Injectie

-

Upload

marinescu-radu -

Category

Documents

-

view

212 -

download

0

Transcript of Tehnica de Injectie

-

8/12/2019 Tehnica de Injectie

1/9

46.2 INJECTION MOLDING

Basic process - Heat a thermoplastic material until it melts. Force it into a hollow

(cooled) cavity under pressure to fill the mold. When cool remove the finished part.

Typical materials are,

. - nylon

!. - styrene". - ethylene

# typical in$ection mouldin% machine is seen &elow with the covers removed. 'lasticpellets are poured in the hopper, and finished parts emer%e from the dies.

n$ection system,

. - a material hopper acts as an input &uffer

!. - a heated cham&er melts the material". - an in$ector forces the now viscous fluid into the mold

'revious mechanisms used an in$ection plun%er.

urrent mechanisms use a reciprocatin% screw,

. - &asically the screw e*tends from the hopper to the in$ection

cham&er.!. - alon% the len%th of the screw cham&er, heater &ands are used to

melt the plastic.

". - as the screw turns, it moves raw solid plastic from the hopper, to

the in$ection cham&er. The &uildup of pressure in the in$ectioncham&er forces the screw &ac+ until enou%h for a shot has

accumulated.. - the screw is forced forward to in$ect the plastic into the mold.

.

-

8/12/2019 Tehnica de Injectie

2/9

. - there is a contri&ution to meltin% &y pressure that allows the

temperature of the heatin% &ands to &e lower.

!. - the purpose of the screw is to %enerate a homo%enous melt with

little orientation in flow direction.

Typical ones can &e identified on the screw,

. - feed - a screw with lar%e cavities to carry more material.!. - compression - the depths of the screw thread reduce, leadin% to

elevated pressures, and pressure induced meltin%.

". - meterin% - small and uniform threads to provide controlled/uantities. This also serves as a final mi*in% sta%e.

0crews are often low1medium1hi%h compression ratio as a result of the chan%e of screw

volume from the feed to the meterin% sta%es - screw selection will vary &etweenmaterials, &ut a low compression ration screw will ensure %ood meltin% in most cases.

0crews are nitride treated to improve tool life. 0crews mi%ht also &e made sli%htlysmaller to compensate for thermal e*pansion when heated.

0crews are often driven &y electric or hydraulic motors.

The heat capacity and meltin% point temperatures of various materials determine the

ener%y re/uired to melt the plastic and the ener%y to &e removed for solidification (andfor e$ection).

-

8/12/2019 Tehnica de Injectie

3/9

The volume of the in$ection cham&er determines the ma*imum mold cavity sie. The

volume provided is often for polystyrene. When usin% other materials the volume can

&e corrected usin% the followin% formula. For e*ample a 2 o. shot,

The mold is held closed with a certain clamp tonna%e.

#s cycle times decrease, the plastic melt &ecomes less consistent.

3ach heatin% one uses electrical heatin% &ands with thermocouples, or pyrometers tocontrol the temperature.

When in$ectin%, the mold is moved then clamped shut. The mold halves aremounted1clamped1screwed on two platens, one fi*ed, one movin%. The stationary

platen has a locatin% rin% to allow positionin% on the mold half over the in$ectionnole. The movin% half has e$ector pins to +noc+ out the finished part. 4ar%er plates

are found on lar%er in$ection moldin% machines.

n$ection moldin% machines pressure is calculated as in$ection pressure over an area in

the mold. onsider the case where a mold with a 2 s/uare inch mold is &ein% filled ina !22 ton machine.

The platens are actuated &y hydraulic driven mechanisms. These are slow, &ut can e*ert

%reat forces. n li%hter presses other mechanisms can &e used.

-

8/12/2019 Tehnica de Injectie

4/9

46.2.1 Hydraulic Pumps/ys!"ms

# %eared hydraulic pump is pictured &elow. 5ther types use vanes and pistons.

-

8/12/2019 Tehnica de Injectie

5/9

Hydraulic systems use pumps to cause fluid flow. 6esistance to that flow will allow

pressure to &uild up. This fluid is directed throu%h a systems with,. - oil filters to clean

!. - heat e*chan%ers to cool oil

". - %a%es to monitor pressure

. - relief valves to release fluid when a ma*imum pressure is passed. - a reservoir to collect uncompressed fluid

7. - chec+ and flow valves

The hydraulic system drives pistons and other hydraulic actuators.

46.2.2 M#lds

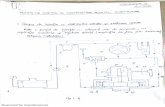

n$ection molds are mainly made of steels and alloys steels. # simple mold is shown

&elow.

-

8/12/2019 Tehnica de Injectie

6/9

. 4ocatin% rin% - %uides the in$ection nole into the mold.

!. 0prue Bushin% - where the in$ected material enters the moldcavities.

". lamp front plate - 0ecures the front cavity, locatin% rin%, and

other components to the stationary platen.. Front cavity - holds half of the ne%ative of the shape to &e molded.

8uide pin holes are put in this plate.

. 6ear cavity - the matin% half for the front cavity that completes thene%ative of the final part. 8uide pins are mounted on this to ensure

correctly ali%ned cavities.

7. 0pacer Bloc+s16ails - used to separate the rear cavity from the rear

clamp plate.9. 3$ector housin% - contains the e$ector pins to +noc+ the parts out of

the mold and forces the cavity &ac+ when the mold is closed.

:. 6ear lamp 'late - 0upports the rear half of the mold on the

movin% platen, and provides ri%idity under moldin% pressures.

omponents to consider in mold desi%n,. - part desi%n

!. - material

". - machine used

Factors that are often altered in the desi%n are,

. - %atin%

!. - runners". - mold coolin%

. - e$ection

8atin% can &e done a num&er of ways

-

8/12/2019 Tehnica de Injectie

7/9

6unners carry the plastic to the in$ection %ates and are often considered disposa&le orreusa&le. Typical runner systems are,

. - cold runner

!. - hot runner". - insulated runner

oolin% systems allow rapid uniform coolin% to increase cycle times, and reduce scrap.Typical techni/ues are,

. - water lines

!. - &affles". - fountains. - thermal pins

3$ection systems will push the part out of the mold when it is opened.. - +noc+out pins

!. - &lades

". - stripper rin%s. - air

. - hard strippin%

46.2.$ Ma!"rials

;aterials often come as raw &eads. These can &e mi*ed, colored, have other materialsadded, or reused.

-

8/12/2019 Tehnica de Injectie

8/9

ommon materials are,

46.2.4 Gl#ssary

Barrel - the cylinder the in$ection screw sits in.

avity1mpression - The two or more hollow metal parts that contain the ne%ative of the

part.old Flow - material that is too cool when in$ected will %et a dull surface finish.

ore - a protrudin% (or male) mold component.

rain% - a fine mesh of crac+s.=e%atin% - separate parts from runners

=elamination - the surface peels off in layers

=owels18uidepins - used to mate mold cavities

=istortion - a warped moldin%

=well - a delay time after fillin% the mold3$ector 'ins - push the part out of the mold as it is opened

Feed - the volume of plastic in$ected into the mold as it is advancedFlash - a thin flat section that has >s/uirted> out of the mold

8assin% - trapped %as mar+s and &urns the mold

8ates - the entry port &etween the runners and the parts8ranules - the pellet form that raw plastic is delivered in.

8ranulation18rinder - will reduce parts to %ranules for reuse

nserts - parts placed in the mold &efore closure and in$ection. These &ecome anem&edded part of the final product

?ole - the plastic is e$ected throu%h the nole to the mold.

'olymers - The chemical cate%ory of plastics'owder - a finely %round material'reheatin% - plastic may &e heated &efore use to remove moisture contaminants

'ur%in% - a few pur%in% shots are made when chan%in% the material

6am - opens and closes the platens6e%rind - reclaimed plastic %ranules

6elease #%ent10pray - # spray, such as silicone, can &e sprayed into ti%ht molds to ease

part removal.6unners - connect the %ate to the sprue

0afety %ate - the %ate must close and shut the operator out for the press to close.

0hot - one in$ection of plastic

0hort shot - insufficient plastic is in$ected0hrin+a%e - reduction in sie as mold cools

0in+in% - 0urface deformation on parts.

0prue - e*cess plastic &etween the in$ector nole and the mold@ent - # small %ap that allows air to escape as it is displaced &y molten plastic

Warped - oolin% stresses cause a part to twist, or warp, to a new shape.

-

8/12/2019 Tehnica de Injectie

9/9