Programare Cu Manual Guide Pe o Piesa Data

-

Upload

favoreel-patrick -

Category

Documents

-

view

228 -

download

0

Transcript of Programare Cu Manual Guide Pe o Piesa Data

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

1/20

APPENDIX

APP1

1 EXAMPLE OF PROGRAMING PROCEDURE

This chapter describes the procedure for creating interactive programs and executing ananimated simulation for beginners of LUCK-BEI (NT Manual Guide i) softwareoperation with examples of simple workpieces.

First, carry out a series of operations of the following examples.

The rules on the brackets described in this chapter are as follows:

Soft-key MDI key Tab Screen Selection of cursor/mode

1-1 O.D. Cutting, End Face Drilling with Y-axis, and Side Face Drilling withC-axisTarget workpiece: Round bar (100 dia.100 mm, end face removal amount 0.5mm)

1st process: O.D turning/rough machining with a general-purpose turning tool (T0101)

2nd process: O.D turning/finish machining with a general-purpose turning tool (T0202)

3rd process: End face drilling by Y-axis with a drill tool (T0303)

4th process: Side face drilling by C-axis with a drill tool (T0404)

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

2/20

APPENDIX

APP2

Displaying NT Manual Guide i screen(1) Select either upper turret or lower turret.

(2) SelectEDIT modewith the MODE selection switch, and then press the functionkey GRAPH.

(3) Main screen of NT Manual Guide i appears.

Fig. 1-1

Creating a new program(1) Press the soft-keyO LIST.

(2) Press the soft-keyNEW.

(3) Enter the program number1000, and then press the soft-keyCREATE.

(4) Move the cursor to the program number 1000, and then press the soft-keyOPEN.

Inputting workpiece figure and start command(1) Press the soft-keySTART

(2) Click the tab WORK, move the cursor to the item Cylinder blank figure, andthen press the soft-keySELECT.

(3) Key-in at each item as shown in Fig. 1-2.

Fig. 1-2

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

3/20

APPENDIX

APP3

(4) Press the soft-keyINSERT.The workpiece definitions entered at the above-mentioned items are inserted intothe program as shown in Fig. 1-3.

Fig. 1-3

(5) Press the soft-keySTART.

(6) Click the tab START, move the cursor to the item 1.START (Y), and thenpress the soft-keyINSERT.The start command is inserted into the program as shown in Fig. 1-4.

Fig. 1-4

(7) Move the cursor to S?, enter numeric value 3000, and then press the keyALTER.

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

4/20

APPENDIX

APP4

1st process (O.D. rough machining)(1) Press the soft-key LO.D..

(2) Click the tabGENERAL, move the cursor to the item1. OD ROUGH+FINISH,and then press the soft-key INSERT.

The fixed form sentence is inserted into the program as shown in Fig. 1-5.

Fig. 1-5

(3) Press the soft-key SRCH, enter numeric value10, press the keyALTERN input.

(4) Press the soft-key SRCH, enter numeric value0101, and press the keyALTERT input.

(5) Move the cursor to T0101, and then press the keyINPUT.TOOL OFFSET screen appears, and the cursor is moved to the No.001.

(6) Press the soft-key GENERL.

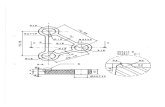

(7) Key-in each item as shown in Fig. 1-6.

Fig. 1-6

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

5/20

APPENDIX

APP5

(8) Click the tab GEOMETRY OFFSET, and key-in each item as shown in Fig.1-7.

Fig. 1-7

(9) Press the soft-keyCLOSE.

(10) Press the soft-key SRCH, enter numeric value120, and press the keyALTERS input.

(11) Press the soft-key SRCH, enter numeric value0.1, and press the keyALTERZ input.

(12) Press the soft-key SRCH, enter numeric value110., and press the keyALTERX input.

(13) Press the soft-key SRCH, enter numeric value0.8, and press the keyALTERX input.

(14) Press the soft-key

SRCH

, enter numeric value

100.

, and press the keyALTERX input.

(15) Press the soft-key SRCH, enter numeric value2., and press the keyALTERU input.

(16) Press the soft-key SRCH, enter numeric value0.3, and press the keyALTERF input.

(17) Press the soft-key SRCH.

(18) With the cursor at thePRESS INPUT KEY, press the key INPUT.The arbitrary geometry input screen appears as shown in Fig. 1-8.

Fig. 1-8

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

6/20

APPENDIX

APP6

(19) First, press the soft-keyALTERfor start point input.Key-in each item as shown in Fig. 1-9.Then press the soft-keyOK.

Fig. 1-9

(20) Press the soft-key LINE.Key-in each item as shown in Fig. 1-10.Then press the soft-keyOK.

Fig. 1-10

(21) Press the soft-key LINE.Key-in each item as shown in Fig. 1-11.Then press the soft-keyOK.

Fig. 1-11

(22) Press the soft-key CC.Key-in each item as shown in Fig. 1-12.Then press the soft-keyOK.

Fig. 1-12

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

7/20

APPENDIX

APP7

(23) Press the soft-key LINE.Key-in each item as shown in Fig. 1-13.Then press the soft-keyOK.

Fig. 1-13

(24) Press the soft-key CR.Key-in each item as shown in Fig. 1-14.Then press the soft-keyOK.

Fig. 1-14

(25) Press the soft-key LINE.

Key-in each item as shown in Fig. 1-15.Then press the soft-keyOK.

Fig. 1-15(26) Press the soft-key LINE.

Key-in each item as shown in Fig. 1-16.Then press the soft-keyOK

Fig. 1-16

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

8/20

APPENDIX

APP8

(27) Press the soft-key CR.Key-in each item as shown in Fig. 1-17.Then press the soft-keyOK.

Fig. 1-17

(28) Press the soft-key LINE.Key-in each item as shown in Fig. 1-18.Then press the soft-keyOK.

Fig. 1-18

(29) Press the soft-key LINE.

Key-in each item as shown in Fig. 1-19.Then press the soft-keyOK.

Fig. 1-19

(30) Press the soft-key LINE.Key-in each item as shown in Fig. 1-20.Then press the soft-keyOK.

Fig. 1-20

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

9/20

APPENDIX

APP9

(31) The contour program is createdas shown in Fig. 1-21.Then press the soft-keyCREATE.

Fig. 1-21

(32) The [METHOD OF CONTOUR PRGRAM CREATION] screen appears. Press thesoft-keyOK.

(33) Press the soft-key SRCH, enter numeric value110., and press the keyALTERX input.

(34) Press the soft-key SRCH, enter numeric value2.0, and press the keyALTERZ input.

1st process (O.D. rough machining) is finished.

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

10/20

APPENDIX

APP10

2nd process (O.D. finish machining)(1) Press the soft-key SRCH, enter numeric value20, and press the keyALTERN input.

(2) Press the soft-key SRCH, enter numeric value0202, and press the key

ALTERT input.

(3) Move the cursor to T0202, and then press the keyINPUT.TOOL OFFSET screen appears, and the cursor is moved to the No.002.

(4) Press the soft-key GENERL.

(5) Key-in each item as shown in Fig. 1-22.

Fig. 1-22

(6) Click the tab GEOMETRY OFFSET.(7) Key-in each item as shown in Fig.1-23.

Fig. 1-23

(8) Press the soft-keyCLOSE.

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

11/20

APPENDIX

APP11

(9) Press the soft-key SRCH, enter numeric value150, and press the keyALTERS input.

(10) Press the soft-key SRCH, enter numeric value50., and press the keyALTERX input.

(11) Press the soft-key SRCH, enter numeric value0.4, and press the keyALTERX input.

(12) Press the soft-key SRCH, enter numeric value30., and press the keyALTERX input.

(13) Press the soft-key SRCH, enter numeric value110., and press the keyALTERX input.

(14) Press the soft-key SRCH, enter numeric value2., and press the keyALTERZ input.

(15) Press the keyPAGE , and move the cursor to the block following afterM01.

2nd process (O.D. finish machining) is finished.

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

12/20

APPENDIX

APP12

3rd process (End face drilling with Y-axis)(1) Press the soft-key L-FACE.

(2) Press the soft-key Y AXIS.

(3) Click the tab DRILL/TAP, move the cursor to the item 8. DRILL (RANDOM)

and then press the soft-key INSERT.

The fixed form sentence data is inserted as shown in Fig. 1-24.

Fig. 1-24

(4) Press the soft-key SRCH, enter numeric value30, and press the keyALTERN input.

(5) Press the soft-key SRCH, enter numeric value0303, and press the keyALTERT input.

(6) Move the cursor to T0303, and then press the keyINPUT.TOOL OFFSET screen appears, and the cursor is moved to the No.003.

(7) Press the soft-keyto display the soft-keyDRILL.

(8) Key-in each item as shown in Fig. 1-25.

Fig. 1-25

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

13/20

APPENDIX

APP13

(9) Click the tab GEOMETRY OFFSET.

(10) Key-in each item as shown in Fig.1-26.

Fig. 1-26

(11) Press the soft-keyCLOSE.

(12) Press the soft-key SRCH, enter numeric value1500, and press the keyALTERS input.

(13) Press the soft-key SRCH, enter numeric value2., and press the keyALTERZ input.

(14) Press the soft-key SRCH, enter numeric value0., and press the keyALTERC input.

(15) Press the soft-key SRCH, enter numeric value20., and press the keyALTERX input.

(16) Press the soft-key SRCH, enter numeric value0., and press the keyALTERY input.

(17) Press the soft-key SRCH.

(18) With the cursor at thePRESS INPUT KEY, press the keyINPUT.

(19) [DRILLINGALTER] screen appears. Key-in each item as shown in Fig. 1-27 andFig. 1-28.

Fig. 1-27 Fig. 1-28

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

14/20

APPENDIX

APP14

(20) Press the soft-key ALTER.

(21) Press the soft-key SRCH.

(22) With the cursor at thePRESS INPUT KEY, press the keyINPUT.

(23) The [XY-RANDOM POINTS-ALTER] screen appears.

(24) Key-in each item as shown in Fig. 1-29, Fig. 1-30 and Fig. 1-31.

Fig. 1-29 Fig. 1-30

Fig. 1-31

(25) Press the soft-key ALTER.

(26) The [METHOD OF FIGURE PRGRAM CREATION] screen appears. Press thesoft-keyOK.

(27) Press the soft-key SRCH, enter numeric value50., and press the keyALTERX input.

(28) Press the soft-key SRCH, enter numeric value5., and press the keyALTERZ input.

(29) Press the keyPAGE , and move the cursor to the block following afterM01.

3rd process (End face drilling with Y-axis) is finished.

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

15/20

APPENDIX

APP15

4th process (Side face drilling with C-axis)(1) Press the soft-key L-SIDE.

(2) Press the soft-key C AXIS.

(3) Click the tab DRILL/TAP, move the cursor to the item 9. DRILLCIRCLEand then press the soft-key INSERT.

The fixed form sentence data is inserted as shown in Fig. 1-32.

Fig. 1-32

(4) Press the soft-key SRCH, enter numeric value40, and press the keyALTERN input.

(5) Press the soft-key SRCH, enter numeric value0404, and press the key

ALTERT input.(6) Move the cursor to T0404, and then press the keyINPUT.

TOOL OFFSET screen appears, and the cursor is moved to the No.004.

(7) Press the soft-keyto display the soft-keyDRILL.

(8) Key-in each item as shown in Fig. 1-33.

Fig. 1-33

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

16/20

APPENDIX

APP16

(9) Click the tab GEOMETRY OFFSET.

(10) Key-in each item as shown in Fig.1-34.

Fig. 1-34

(11) Press the soft-keyCLOSE.

(12) Press the soft-key SRCH, enter numeric value1500, and press the keyALTERS input.

(13) Press the soft-key SRCH, enter numeric value38., and press the keyALTERZ input.

(14) Press the soft-key SRCH, enter numeric value0., and press the keyALTERC input.

(15) Press the soft-key SRCH, enter numeric value70., and press the keyALTERX input.

(16) Press the soft-key SRCH.

(17) With the cursor at thePRESS INPUT KEY, press the keyINPUT.

(18) [DRILLINGALTER] screen appears. Key-in each item as shown in Fig. 1-35 andFig. 1-36.

Fig. 1-35 Fig. 1-36

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

17/20

APPENDIX

APP17

(19) Press the soft-key ALTER.

(20) Press the soft-key SRCH.

(21) With the cursor at thePRESS INPUT KEY, press the keyINPUT.

(22) The [ZCC AXIS HOLE (ARC POINTS)ALTER] screen appears.

(23) Key-in each item as shown in Fig. 1-37 and Fig. 1-38.

Fig. 1-37 Fig. 1-38

(24) Press the soft-key ALTER.

(25) The [METHOD OF FIGURE PRGRAM CREATION] screen appears. Press thesoft-keyOK.

(26) Press the soft-key SRCH, enter numeric value70., and press the keyALTERX input.

(27) Press the soft-key SRCH, enter numeric value2., and press the key

ALTERZ input.

(28) Press the keyPAGE , and move the cursor to the block following afterM01.

(29) EnterM30;at the end.

4th process (Side face drilling with C-axis) is finished.

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

18/20

APPENDIX

APP18

Checking process list on process edit screen(1) Select EDIT mode with MODE selection switch, and then press the soft-keyPROCES.Process check is available on PROCESS EDIT screen.

Fig. 1-39

Checking by animated/solid simulation(1) Select MEM mode with MODE selection switch, and then press the soft-keySIMLAT.

(2) Press the soft-key REWID.

(3) Press the soft-key START.The animated simulation is executed.

Fig. 1-40

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

19/20

APPENDIX

APP19

2 NT MANUAL GUIDE PARAMETERS2-1 Parameters Used for NT manual Guide

In NT Manual Guide i, the standard parameter range: parameter number P7295 7299 of NC unit is used.

Concerning to above mentioned range of parameters, the contents that are described inthis manual is prior to the contents that are described in the manual of FANUC NCunit.

NOTE: Some of the NT Manual Guideparameters become valid only after the poweris switched off and on again. Therefore, for the sake of safety, after changing thesettings of parameters, switch off the power once.

NOTE: Some NT Manual Guide i parameters serve multiple functions. Setting valuesfor them are expressed as shown blow: 1, 2, 4, 8 ...0: Function A invalid1: Function A valid

0: Function B invalid2: Function B valid

0: Function C invalid4:Ffunction C valid

0: Function D invalid

8: Function D valid

Setting value=0 All the functions are invalidSetting value=1 Only function A is validSetting value=2 Only function B is validSetting value=3 Functions A and B are valid (1+2=3)Setting value=4 Only function C is validSetting value=5 Functions A and C are valid (1+4=5)Setting value=6 Functions B and C are valid (2+4=6)Setting value=7 Functions A, B and C are valid (1+2+4=7)Setting value=8 Only function D is validSetting value=9 Functions A and D are valid (1+8=9)

Setting value=10 Functions B and D are valid (2+8=10):

Setting value=15 All the functions are valid (1+2+4+8=15)

NOTE: Setting ranges and setting units of NC parameters differ depending on the NCtype. Set NC parameters according to the type of NC installed in the machine.

FS-0/16/18/21 series : FANUC Series 0/16/18/21 series

FS-30/31/32 series : FANUC Series 30/31/32 series

-

7/28/2019 Programare Cu Manual Guide Pe o Piesa Data

20/20

APPENDIX

2-2 Descriptions of NT Manual Guide i Parameters

P7295 Setup for soft key display

Display of the soft key of FANUC standard turning/ milling cycle on the 4th page during

EDIT mode is

0: Invalid

1: Valid

P7296 Setup for the fixed form sentence menu selecting function

When inserting a fixed form sentence, automatic insertion of the spindle selectingG-code (L-spindle: G1998 S1/ R-spindle: G1998 S2) for the animation is;

0: Valid

1: Invalid

When inserting a fixed form sentence, automatic insertion of the work coordinate systemselecting G-code (L-spindle: G54/ R-spindle: G55) is

0: Valid

2: Invalid

Fixed form sentence edit function

0: Invalid

4: Valid

NOTE: The validity/ invalidity of this function is determined by theparameter setup of turret head 1.

NOTE: Setting this function to valid adds interface soft-key below the USER tabdisplayed by pressing the soft-key OTHR, and also displays fixed formsentence IDs on the fixed form sentence selection screen.

NOTE: This function is available in a software NT NURSE of version V7.60or higher.

NOTE: The validity/ invalidity of this function is determined by the parametersetup of turret head 1.

NOTE: This function should be set up by each turret head. (Available on thesoftware V7.52 or higher.)

NOTE: Display/non-display of soft-keys is changed by the parameter setup of turrethead 1.